Under the current development of cleaner production conditions, with the higher and higher requirements for dust-free grade, dust-free wiping products are also sought after by users. Indeed, dust-free wipes can bring unprecedented "cleanliness" to cleaner production.

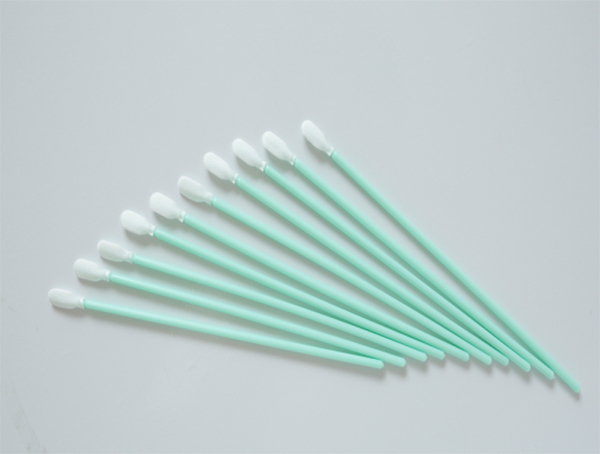

At present, the common dust-free rags with good effects are dust-free rags and dust-free rags, which can no longer meet the needs of our industry for micro pollution control. However, there is a very easy-to-use micro pollution wipes, that is, dust-free cotton swabs, also known as dust-free wiping cloth. It can effectively remove small particles on products or product carriers, and has become the best tool. Precision testing. However, there are many kinds of dust-free cotton swabs. How should users choose the most suitable dust-free Cotton Swab? Let's take a look at the material classification of dust-free cotton swabs: Dust free purification cotton swab (also known as dust-free wiping stick) is essentially different from ordinary cotton swab: The material of ordinary cotton swab head is cotton. It cannot be cleaned without dust and may be scraped off during wiping; It can only be wiped with products in ordinary environment, such as ordinary Medical Cotton Swabs, beauty cotton swabs, etc; The materials of dust-free cotton swab head / wiping rod are divided into sponge head and cloth head, which have been cleaned and packaged in the dust-free room. Therefore, the wiping consumables used in the advanced dust-free environment must reach more than 100. Only the dust-free cotton swab can meet the requirements, such as huby purification cotton swab, which is mainly used to wipe accessories and dust in HDD, PCB, FPD, lens, semiconductor and other industries. At present, huby cotton swabs are widely used not only in Japan, but also in China, Thailand, the Philippines, Taiwan, South Korea, the United States, Europe and other countries and regions. It can be said that huby cotton swab has become the most famous brand in Industrial cotton swab.

If we distinguish the dust-free purification cotton swab from the material of the head, we can say that it is more refined and more specific: the material of the head is more than the above two, and we have seen it in the market: 1. Cloth ends can be divided into the following types according to different fabrics and their functional properties: A: knitted nylon cloth (super wear-resistant) B: Knitted microfiber (wipe fine dust, average wear-resistant)) C: woven microfiber (fiber wiping specialty) d: knitted polyester (longitudinal grain on the cloth surface, deep gap, can accommodate more dirt). Dust-free cloth ends above cotton swabs can be cleaned in class 100 rooms, Suitable for electronic use. 2. The sponge head can be divided into the following two types according to the density and chip removal of the sponge: perforated Pu sponge, 100ppi (PPI -- port per inch, refers to the number of holes per inch, the more the number), the finer the sponge, the lower the sponge density, easy to drop chips, but the water absorption speed is fast, which is suitable for medical use; b: Perforated Pu sponge, 400-500ppi, has higher density than 100ppi sponge, is not easy to break, and has high dust-free grade. It is suitable for electronic use. 3. The grade of non-woven head is low, but the processing difficulty is small and the price is cheap. 4. The excellent elasticity and softness of PVA head make it not leave scars; It is different from the wiping cloth in the form of textiles and non-woven fabrics. There is fuzzing; Amazing self generating ingredients make it reusable; Super absorbent, can quickly absorb water, the amount is 6 times its own; Extensive hydrophilicity makes it compatible with water and various organic materials; Never dust, no silicon, no bread crumbs, environmentally friendly and degradable. After professional treatment, it has good chemical resistance, no mildew, Grade 100. Wide range of uses, good prospects! It can be used in electrical appliances, semiconductors, liquid crystal displays, optics, precision instruments, window cleaners and absorbent materials for dust-free rooms in industrial departments.