The anti-static dust-free cloth is made of 100% polyester fiber, with soft surface, easy to wipe sensitive surface, no fiber falling off after friction, good water absorption and cleaning efficiency. Product cleaning and packaging are completed in the super clean workshop. Anti static dust-free cloth generally appears in dust-free workshops, but also in the electrical industry. Dust free is the standard of electrical appliances.

There are also precautions when using dust-free cloth. As a special wiping product, anti-static dust-free cloth is one of the most important products in industrial production. It is different from ordinary wiping paper. It has wear resistance and tear resistance. It has the advantages of crack resistance, good elasticity, no dust, no hair, strong water absorption and so on. We must make good use of these advantages and give full play to their role.

Wear dust-free gloves and masks before unpacking. For high-grade fiber dust-free cloth, it is necessary to unpack in a clean environment. Before unpacking, clean the packaging bag, especially the opening, and keep it for standby.

Secondly, when we use a dust-free cloth to wipe the sensitive surface, fold the edge of the dust-free cloth and wipe only the middle part of the dust-free cloth, so as to minimize the damage to the sensitive object; The dust-free cloth can directly wipe the object surface or add solvent to wipe it.

During operation, the dust-free cloth must be kept flat and do not rub at will. When moving and wiping, try to make the fiber of the cloth fully contact with the surface, and keep the wiping direction consistent. Do not wipe repeatedly from time to time.

Although dust-free cloth is a wiping product with very high requirements for cleanliness, it can be well cleaned and maintained and can be used repeatedly. Polyester dust-free cloth is woven from 100% polyester fiber and generally adopts laser edge sealing, which can effectively prevent dust and silk falling. How to maintain polyester dust-free cloth after use?

Clean with a dust-free cloth

1: Before cleaning, soak it in warm water to ensure that the stains fall off.

2: Choose a cleaner with neutral pH value for cleaning. In addition, if you want to remove stains more conveniently, you'd better heat the water appropriately. Do not use bleach because the fiber will become brittle after washing.

3: After cleaning, it needs to be thoroughly washed with non-ionic pure water. Make sure there is no residue on the polyester dust-free cloth.

4: Do not iron or expose to the sun after cleaning, which will damage the fibrous tissue in the dust-free cloth. If there is a dryer, it is best to use a hot air dryer and adjust it to low temperature drying.

Microfiber dust-free cloth may feel thinner when used for the second time after cleaning. This is because the filament shrinks during cleaning. Choose a high-quality dust-free cloth, and you will find that even after cleaning, the material and feel of the cloth are the same as when you first use it. If you clean it, the whole cloth looks new, white, soft and tough.

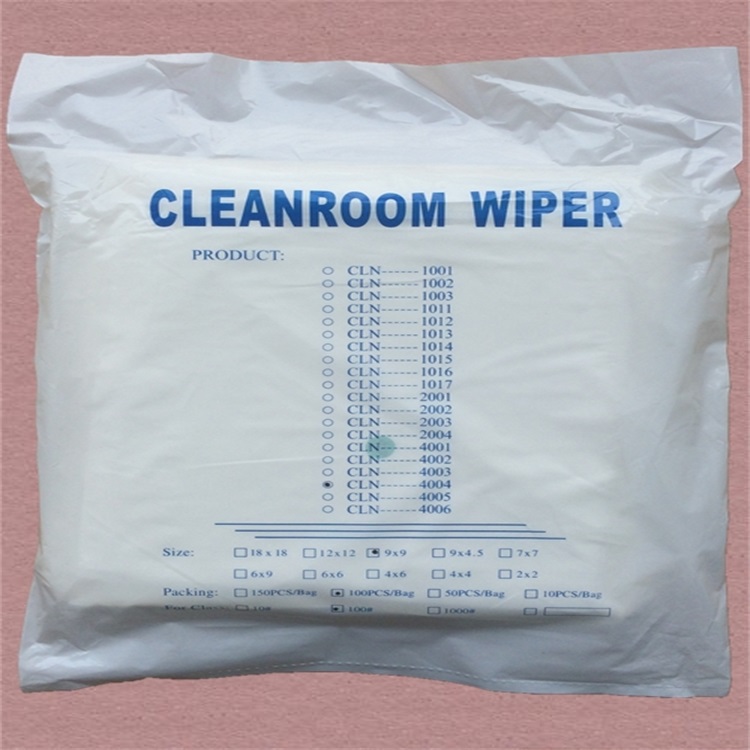

At present, there is no unified definition of the model of dust-free cloth in the national standard. We can divide the dust-free cloth from the model, specification and classification at most. At present, the dust-free cloth is basically only the difference in application, such as photoelectric application, semiconductor application, hard disk factory application, etc. Let's take a look at the model and specification of the dust-free cloth.

(1) Fiber size classification includes: Polyester dust-free cloth, sub microfiber dust-free cloth, imitation microfiber dust-free cloth and microfiber dust-free cloth.

(2) According to the purification level, there are: Grade 10 dust-free cloth, Grade 100 dust-free cloth, grade 1000 dust-free cloth and grade 10000 dust-free cloth.

(3) Classification by product model: 1009s straight grain polyester dust-free cloth, 1009D reticulated polyester dust-free cloth, 2009 sub microfiber dust-free cloth, 3009 anti microfiber dust-free cloth, 3009a microfiber dust-free cloth, 4009 microfiber dust-free cloth, 6009 microfiber cleaning cloth, 16404 microfiber cleaning cloth, 7009 microfiber cleaning cloth and 8001 microfiber cleaning cloth.

(4) According to the size classification, the conventional sizes are 4 * 4 inches, 6 * 6 inches and 9 * 9 inches.

The wide use of dust-free cloth is inseparable from its many unique properties and functions. The dust-free cloth has good water and oil absorption to ensure effective removal of oil and water on the equipment surface. Some solvents can be used to remove dirt remaining on the surface of the equipment.

![]() August 09, 2021

August 09, 2021